The Joint Assessment of International Consulting Companies Regarding Lydian’s Amulsar Gold Mining Project is Negative

Experts from three internationally acclaimed companies, such as Blue Minerals Consultancy from Australia, Buka Environmental from the USA and Clear Coast Consulting, Inc., Canada have studied more than a dozen documents available on Lydian International’s website and have given their opinion regarding some of the ecological risks of the gold mining project. Based on their assessments they have presented a joint summary of findings and recommendations titled:

“The overall recommendation is that mining should not start until the environmental outstanding issues are properly investigated by independent bodies/consultants. Their findings should be incorporated into an acid and metalliferous drainage (AMD) management plan that includes and makes explicit both government and company responsibilities and liabilities.”

Below are the the main highlights of the expert summary:

“Potential Impacts

Most importantly, there is a significant risk of acid and metalliferous generation and discharge from this site that will continue long after mining ceases. This risk exists in spite of measures proposed by Lydian to prevent AMD generation after closure of the proposed mine.

The site includes important biodiversity habitat for animals and plants.

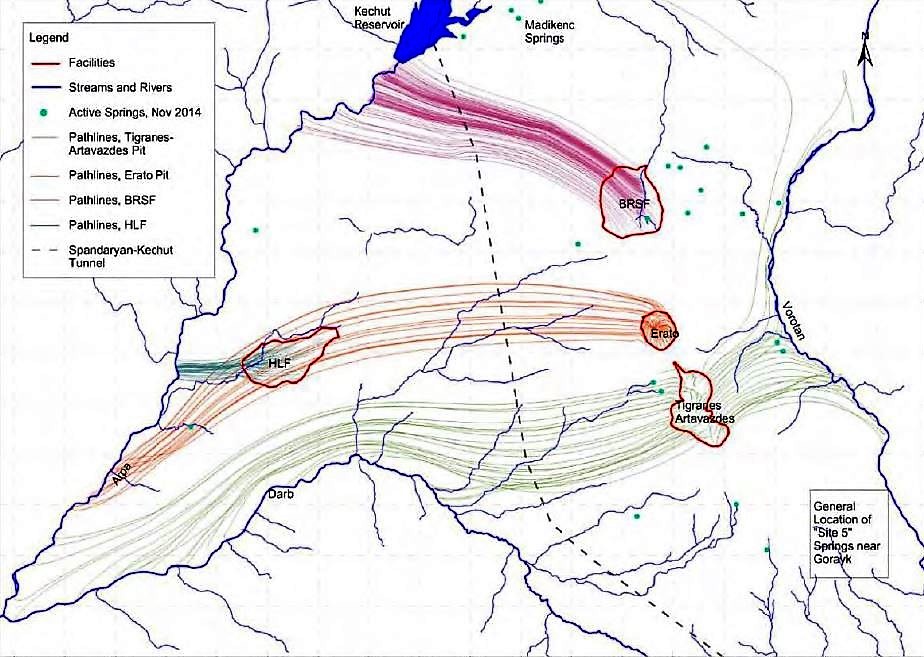

Predicted (modelled) changes in groundwater levels (e.g. up to 60 m lower), redirection and reduction in springs and streams within and around the mine site are of considerable magnitude.

Significant impact to water quality at springs located around the pits is predicted with respect to beryllium, cobalt, nickel and nitrate as a result of leakage from the pits.

There is also a significant impact predicted to groundwater quality adjacent to the Vorotan River as a result of leakage from the pits.

There is a potentially significant predicted impact to groundwater input to the Spandaryan-Kechut Tunnel.

Insufficient Geochemical Testing

- Significantly more mineralogical, geochemical and acid-base accounting testing is required for prediction of acid rock drainage rates and their evolution with time. This testing should include a significant number of long-term laboratory kinetic tests and pilot-scale field tests.

It has not been recognised by Lydian that in control of acid rock drainage in the first 10 years, it is rates rather than total amounts that determine the mitigation required.

The amount of material to be extracted during the Amulsar Project suggests that over 2,000 samples should be examined for acid-base accounting whereas approximately 200 samples have been examined.

In addition, geochemical testing has been conducted on too few samples and these have not been representative.

– Only eleven Lower Volcanic rock samples and seven Upper Volcanic samples were analyzed for mineralogy.

– Only eight kinetic tests were conducted.

Inaccurate Assessment

- The contributions to acid generation from the minerals alunite and jarosite need to be properly defined and accounted for in the management plan.

It is implied by Lydian that mine drainage with a pH as low as 4.5 is acceptable whereas the international GARD Guide uses a cut-off of pH 6. Acid rock drainage from on-site Soviet waste dumps with pH 3.5 is found after 65 years of storage and weathering. Two of the five Lower Volcanic wastes that were subjected to kinetic testing gave rise to effluent pH values below 3. This is serious acid rock drainage.

The reoccurring statements regarding “resistance to the formation of strong ARD and resistance to ARD created by ferric iron oxidation of sulfides.” are incorrect.

The acid producing minerals jarosite and alunite are found in both the Upper and Lower Volcanics. Acid generation from alunite leaching is discounted as not being significant and acid generation from jarosite leaching is not recognised at all.

High Levels of Potential Metal Release

Ammonia, antimony, arsenic, beryllium, bismuth, cadmium, copper, lead, manganese, mercury, molybdenum, nickel, nitrate, selenium, silver, oil and grease, vanadium, and zinc are all predicted to be released into water ways at concentrations of potential concern.

Barren Rock

Kinetic testing of acid producing samples was stopped before maximum or steady state concentrations were reached; therefore, reasonable estimates of the effects on nearby streams and groundwater cannot be made.

The high “early flush” acid and metal concentrations indicate the type of water quality that could be produced after snowmelt or a rainstorm from weathered materials in the barren rock storage facility, the open pits, and the heap leach facility.

The initial concentrations of arsenic released from Upper and Lower Volcanic rocks were significant with in one instance arsenic concentration over 20× greater than the US, European Union, Australian, Canadian, and South African drinking water standards.

Heap Leaching

- Estimates should be made of mercury released to the atmosphere, including from active heaps, carbon columns, carbon regeneration, and the mercury retort, and mercury capture methods should be proposed to limit mercury releases to workers and the environment. In addition, mercury concentrations in the Arpa River and in groundwater down-gradient of the heap leach facility should be estimated using a range of predicted heap leach drain-down concentrations.

A mercury concentration over 10× greater than the US drinking water standard and the World Bank discharge standard was predicted in heap leach facility drain-down water after detoxification.

Untested and Insufficient Mitigation Strategies

The working hypothesis made by Lydian is that if they mine quickly and place covers over the barren rock storage facility, acid drainage will not have a chance to form. This is a false assumption.

The proposed passive treat systems for the closed Amulsar mine will not fully detoxify water. The conceptual design proposed by Sovereign will fail because it is not designed to treat acidic drainage that contains elevated aluminum and iron concentrations.

Barren Rock Storage Facility

- Encapsulation of potentially acid generating Lower Volcanic rock in Upper Volcanic barren rock as a means to control acid and metal release must be tested.

The Upper Volcanics acid generation behaviour is characterised as Uncertain to Potentially Acid Generating, so it is possible the encapsulation material may itself release acid. Additionally, Upper Volcanic rock has a strong potential to leach arsenic, antimony, and other contaminants, even under neutral pH conditions.

The encapsulated barren rock storage facility will be covered by 1.0 meter of clayey subsoil covered with 0.2 meters of topsoil. Highly-reactive sulfides will generate hot spots that will stress the soil cover. Additionally, rapid weathering of highly-reactive rock may also decrease the structural integrity of the rock and result in uneven settling and subsidence of the pile. Taken together, these effects may breach the integrity of the soil cover, which would negate its benefit and result in long-term ARD generation.

Pit Dewatering during Operation

Pit dewatering is predicted to produce flows of 63−100 L s1. This water will comprise acidic groundwater that will drain to the pit bottom. During operation this will be pumped out of the pits and mixed with the seepage from the barren rock storage facility.

Passive Water Treatment

- A lime plant with a clarifier should be used to treat the acidic drainage anticipated during mine operation. During that time, predictions of water quality at mine closure should be improved and the design for a passive treatment system at closure should be tested, if warranted.

- In the case of the biochemical reactor (passive treatment) designed to remove sulfate, it needs to be demonstrated how this will achieve their discharge goals in the long-term because such systems have not been tested for the Amulsar Project.

- The proposed passive treatment polishing step (sulfide scrubber and biological oxygen demand removal) need to be demonstrated, particularly the long-term performance and viability of the sulfide removal process.

- Lydian needs to demonstrate that these systems can be operated reliably year-round for decades or longer, and that staff under their authority will be sufficiently competent to maintain these systems, identify malfunctions and develop appropriate corrective actions. The company or the government needs to demonstrate that it has the resources to operate and maintain these systems for at least 100 years, which is, at a minimum, how long they will likely need to be operated.

No studies have been performed to evaluate the performance of the proposed passive treatment system for the combined seepage from the barren rock facility and pit dewatering (during operation).

If this approach fails a completely new and significantly more expensive active treatment plant must be designed, built, and tested well in advance of mine construction.

Heap Leach Facility

- A design for the active and passive treatment systems must be provided to treat pre- and post-closure drainage from the heap leach facility.

Operation of the heap will mobilize a number of toxic metals/metalloids and create new toxic complexes. Cyanide will form highly soluble complexes with metals like cobalt and mercury. Additionally, antimony, arsenic and selenium may be complexed with cyanide.

All these complexes will build up in the leach solution or form solid compounds in the heap, as the leach solution is continually recirculated. It is necessary to know how elements and complexes like arsenic, mercury or thiocyanate will be removed when the heap is decommissioned.

Pit Drainage Post-closure

There are no plans to treat the acidic drainage discharged by the closed pits. Instead, pit water is predicted to infiltrate the pit bottoms and seep to springs. This drainage could have significant impacts on the environment. Instead, it should be pumped or directed for treatment in the same manner as seepage from the barren rock storage facility prior to discharge to waterways.

Monitoring, Risk Mitigation and Management

- The Armenian government should seek international expertise to evaluate the ARD risk from development of the Amulsar Project.

- Additional seasonal data and additional wells or piezometers are needed around the planned outline of the pits to evaluate the likelihood of bedrock groundwater inflow to the pit during mining. As pit seepage will make its way into spring waters, both spring and ground water should be monitored off and on-site for > 50 years.

- The legal responsibility for remediation of mine discharges after closure must be identified and documented. This responsibility must mitigate against bankruptcy of Lydian or the mine being sold.

- There is no clear assigned responsibility for implementation of the acid rock drainage management plan in the company or government. Specifically, there is no assignment of responsibility for ensuring that the identification and placement of the higher risk Lower Volcanic barren rock during operation occurs in a manner that protects water resources. This must be rectified.

There are insufficient risk mitigation strategies in place.

Given that acid seepage is likely to peak after the proposed five-year on-site monitoring and may continue for decades or centuries, a longer period of monitoring is needed.

The Amulsar Project falls short of leading practice in the industry because it does not propose multiple mitigation measures to minimize the effects of acid drainage.

Neither the ESIA (Environmental & Social Impact Assessment, June 2016) nor any other mine document contains a contingency plan for construction or use of an active treatment plant during or after mining. This is a reasonable, conservative, base case scenario that should be required.

It appears that there is no expertise within the Armenian Government to recognise, assess, monitor the Amulsar ARD mitigation or control this potential release for the Armenian people.”

For full evaluation, please review the detailed documents (see here), recommended that this summary be read in conjunction with Section 26 Recommendations, NI 43-101, March 30, 2017, prepared for Lydian by Samuel Engineering (see here) in which major additional design and testing for the heap leach facility, barren rock storage facility, geochemistry, water treatment and water balance are proposed.

Armenian Environmental Front (AEF) civil initiative

armecofront@gmail.com